Magnet Assembly Types

Select your desired magnet assembly type below for more information:

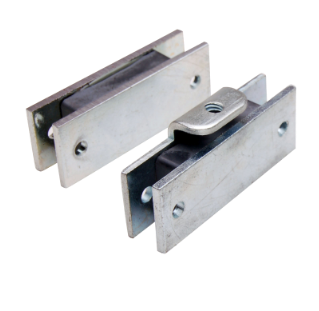

Channel / Sandwich

Magnet Assemblies

High-grade Ceramic with Zinc-plated steel housing. Increased holding force in a small assembly.

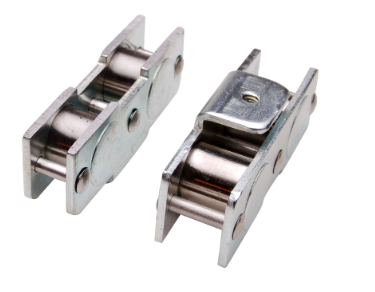

Racking Magnet Assemblies

Designed using high-temp Alncio magnets and mechanical fasterns – good to 800°F

Custom Magnet Assemblies

Designed to your need using 2D/3D modeling to efficiently build to your requirement.

Engineered to Order (ETO) Magnetic Assemblies and Custom Assemblies (Application Specific)

Dura Magnetics specializes in the development and fabrication of application-specific magnet assemblies, from creating a variation of an existing product to new product formation. Learn more about our solutions and contact us for assistance in conceptualizing, designing and manufacturing your custom magnet assembly.

Magnet Assembly Concept Validation

Magnetic concept validation is used to determine whether a magnet solution is viable. This process involves design exchanges between team members, drawing reviews, first order software simulations, and geometry mock-ups of the assembly. Our magnetic validation process helps ensure a concept that meets your performance, cost, and timeline requirements.

Dura Magnetics can assist with assembly design or be commissioned to provide a turn-key solution based on the variables outlined in concept validation. The development stage will make use of Dura Magnetics’s accumulated knowledge base acquired since 1961, 2D and 3D Boundary and Finite analysis simulation software, prototype construction, and empirical testing.

Dura Magnetics maintains an extensive in-house assembly manufacturing capability and augments certain skill-sets by managing relationships with a variety of key vendors. Our design and development process will take into account the target manufacturing location’s capabilities so as to ensure a simple conversion from prototype to production levels.

With in-house coordinate measuring machines (CMM) and Hysteresigraph (which measures magnetic strength of a chosen sample), Dura Magnetics can quantify and qualify an existing magnet assembly for optimization or for duplication.

What are Magnetic Assemblies?

A magnetic assembly incorporates magnet alloy and non-magnet material. Magnet alloy is very hard and even simple features are difficult to incorporate into the alloy. However, the magnetic components of these assemblies allow for a variety of functions.

Mounting- and application-specific features are easily incorporated into the non-magnetic materials, which usually form the housing or magnetic circuit elements. The non-magnet elements will also buffer the brittle magnet material from mechanical stress and increase the overall magnetic strength of the magnet alloy.

Combining integrated magnetics with non-magnet elements creates assemblies with the performance, functionality, durability, and power to achieve your goals. From simple assemblies to highly complex magnetic devices, Dura Magnetics has the precision magnetic manufacturing capabilities to create solutions that perform.

Dura Magnetics specializes in the design and optimization of assembly elements by the use of 2D and 3D BEA/FEA simulation software. We can help you with both stock and engineered-to-order precision assemblies to suit your needs.

Strength of Magnet Assemblies

Magnetic assemblies typically have higher magnet force when compared to a magnet by itself because the flux conducting elements (steel) of the assembly are often an integral part of the magnetic circuit. These elements, by the use of magnetic induction, will enhance the assembly’s field and focus it to the region of interest.

This technique works best when using the magnetic assembly in direct contact with the work-piece. Even small gaps can dramatically impact the magnetic force. These gaps can be an actual air-gap or any coating or debris which stands the assembly off of the workpiece.

Mounting Magnet Assemblies

Magnetic assemblies can be integrated by a variety of methods, most of which are mechanical. The most common are press-fitting (interference) and by the use of a mechanical fastener.

The press-fit assemblies will typically utilize a brass sleeve which is centerless-ground for insertion into a bore. Mechanical fastener mounting will make use of an incorporated tapped or through hole in the assembly.