Designers and engineers that need to incorporate a magnet into their application are often not fully aware of the mechanical characteristics of magnetic alloys. Features that are commonly specified and produced on materials such as mild steel, stainless steel, aluminum, or brass can be very difficult to produce on a magnet or incorporated into magnet assemblies.

Much of the difficulty is based on the composition of the magnetic alloy which is characteristically hard and brittle. Hard and brittle is a short phrase that can be repeated quite a bit when discussing the characteristics of magnets.

Default title-block pitfalls:

Many magnet drawings have ‘title-block default’ specifications and tolerances which, while can be applied, may add costs that are not warranted. Some of the features and geometric dimensioning and tolerancing (commonly referred to as GD&T) that is typically controlled by default in the title-block are: surface finish, dimensional / angular tolerances, and radii / fillets. These “defaults” can be supplied, but one must question if they are truly necessary to the fit and function of the application. They should be applied purposefully and not be treated as “boiler-plate,” as integrating them may add cost.

Many magnet drawings have ‘title-block default’ specifications and tolerances which, while can be applied, may add costs that are not warranted. Some of the features and geometric dimensioning and tolerancing (commonly referred to as GD&T) that is typically controlled by default in the title-block are: surface finish, dimensional / angular tolerances, and radii / fillets. These “defaults” can be supplied, but one must question if they are truly necessary to the fit and function of the application. They should be applied purposefully and not be treated as “boiler-plate,” as integrating them may add cost.

Surface finish and edge breaks – Alloy manufacturing method:

Most permanent magnets are produced by either casting or sintering processes. In the absence of dimensional control, the alloy is left in an ‘as cast’ or ‘as sintered’ condition. Abrasive grinding is the most common method of achieving better surface finishes. Edge break requirements are applied by abrasively tumbling or grinding. Simple deburring operations, commonly used on conventional materials, are not possible due to the hardness and brittle nature of the material. For this reason we would caution designers against arbitrarily tight tolerances on edge breaks and other features that do not impact fit and function.

Most permanent magnets are produced by either casting or sintering processes. In the absence of dimensional control, the alloy is left in an ‘as cast’ or ‘as sintered’ condition. Abrasive grinding is the most common method of achieving better surface finishes. Edge break requirements are applied by abrasively tumbling or grinding. Simple deburring operations, commonly used on conventional materials, are not possible due to the hardness and brittle nature of the material. For this reason we would caution designers against arbitrarily tight tolerances on edge breaks and other features that do not impact fit and function.

Corrosion inhibitors:

Corrosion prevention and improved cosmetic appearance are two prominent benefits that are a result of coating or plating a magnet. Plating processes have been optimized for many magnetic alloys; however, unlike typical metal plating options for other commercial materials, Service Codes (SC), indicating performance in various environments, and adherence to an association specification are not always available. Regardless of the type of plating, magnets should not be designed to work in aggressive operational environments.

Corrosion prevention and improved cosmetic appearance are two prominent benefits that are a result of coating or plating a magnet. Plating processes have been optimized for many magnetic alloys; however, unlike typical metal plating options for other commercial materials, Service Codes (SC), indicating performance in various environments, and adherence to an association specification are not always available. Regardless of the type of plating, magnets should not be designed to work in aggressive operational environments.

Mechanical features:

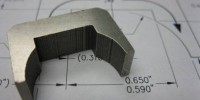

Fabricated features such as holes, shoulders, tapers, and grooves can be integrated into many of the magnetic alloys we supply. Usually the required tolerance for these features do not allow for casting or sintering them directly and they are normally produced by abrasively grinding or electrical discharge machining (EDM). Low stock removal during grinding, due to the fragility of the alloy, adds cost. Also, the high resistivity of magnet alloy results in long EDM burn times and undesirable ID tapers which require additional fabrication time to correct and therefore add cost to finished pieces.

Fabricated features such as holes, shoulders, tapers, and grooves can be integrated into many of the magnetic alloys we supply. Usually the required tolerance for these features do not allow for casting or sintering them directly and they are normally produced by abrasively grinding or electrical discharge machining (EDM). Low stock removal during grinding, due to the fragility of the alloy, adds cost. Also, the high resistivity of magnet alloy results in long EDM burn times and undesirable ID tapers which require additional fabrication time to correct and therefore add cost to finished pieces.

One note of caution, permanent magnets are very prone to fracturing when flexed or stressed in tensile. Regardless of whether the magnets have simple or more complicated features, they should not be specified or used as a structural design element.

Design consideration:

Although the fabrication methods discussed earlier exist as options to produce complex features on magnets, it may make sense to avoid these processes and integrate a less complex magnet. Often a cursory review of a magnet drawing is enough to provide valuable feedback on what is and what isn’t a feasible magnet. Magnetics design engineers can successfully assist your design team in developing a manufacturing approach that yields a magnet meeting the application requirements while mitigating unnecessary costs and longer lead times.

Although the fabrication methods discussed earlier exist as options to produce complex features on magnets, it may make sense to avoid these processes and integrate a less complex magnet. Often a cursory review of a magnet drawing is enough to provide valuable feedback on what is and what isn’t a feasible magnet. Magnetics design engineers can successfully assist your design team in developing a manufacturing approach that yields a magnet meeting the application requirements while mitigating unnecessary costs and longer lead times.

Dura Magnetics’ engineers daily help companies develop complex design-for-manufacturability solutions. Our technical expertise is recognized as helping drive decisions that impact cost, product mass, and often ease of manufacturing magnetic assemblies. Please contact us for help with magnetic design or application assistance.