When selecting a style of Synchronous Magnetic Torque Coupler, one must consider the type and how the coupler will be integrated to ensure a trouble free performance. The style of coupler, Face-to-Face or Coaxial, will generally be dictated by the requirements of the application, but the ability to ensure correct radial, axial, or angular alignment will also need to be considered.

Each style has tolerance levels for various misalignment conditions. When the coupler halves are misaligned, there may be no issue, or there could be degradation in the torque transfer to serious mechanical failures.

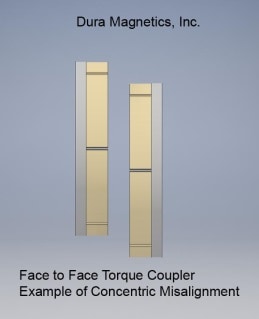

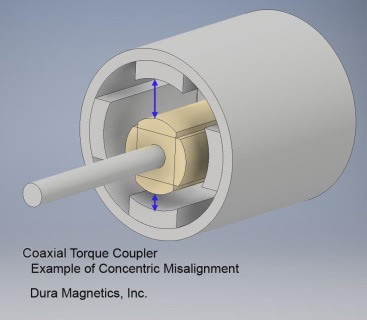

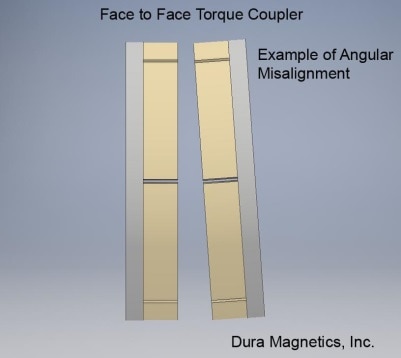

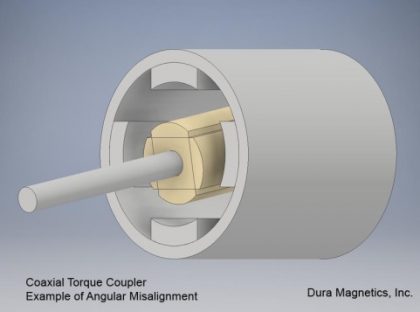

Each Magnetic Torque Coupler style, Face-to-Face and Coaxial, have somewhat different reactions to the geometric misalignments.

The misalignment conditions are defined as:

Axial Misalignment: The position of each coupler half along the rotational axis of the system.

Radial Misalignment: The concentricity of the two halves relative to one another. (The delta between the rotational axes of the two coupler halves.)

Angular Misalignment: The angle between the rotational axes of the two coupler halves.

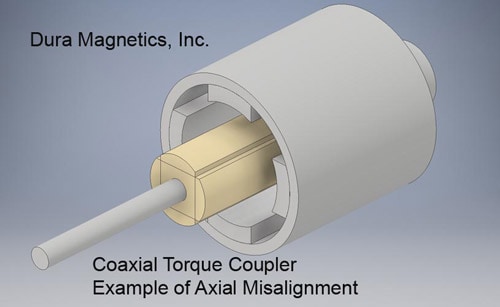

Effects of Geometric Misalignments on Coaxial Style Magnetic Torque Couplers:

Axial Misalignments: (Very Low Impact) –

Coaxial style couplers with an axial misalignment suffer very little impact other than a slight reduction of torque. As the Coaxial Coupler halves are designed to “nest”, there is an axial force created by the magnetic field to completely align the halves axially. When there is an axial shift and this axial alignment force is created, it can put some axial load of the system.

Radial Misalignments: (Moderate Impact) –

When the Coaxial Coupler halves have a delta between their rotational axes, one side of the coupler halves is closer than the other. This creates a radial unbalance which can cause a reduction in torque transfer, vibration, and radial loads. This can negatively impact the mechanicals of the coupler. (Also, when a Coaxial Coupler is used for instrumentation that requires a sinusoidal output and a radial misalignment exists, distortions of the sinusoidal symmetry can occur.)

Angular Misalignment: (Moderate Impact) –

Like the Radial misalignments, the Angular misalignment creates an unbalance, but it is not symmetric about the rotational axes of the couples.

Effects of Geometric Misalignments on Face-to-Face Magnetic Torque Couplers:

Axial Misalignments (Moderate to High Impact) –

Face-to-Face style couplers are attracting axially, and the net torque transfer capability is a function of the gap between the coupler halves. If the gap is increased, there is an exponential degradation of the net torque.

Radial Misalignments (Low Impact) –

When the Face-to-Face Coupler halves have a delta between their rotational axes, less magnets overlap, but there are no radial force components created which impact the mechanicals of the system. There may be a slight torque degradation, but by magnetic coupler standard, the impact is quite low.

Angular Misalignment: (Low to Moderate Impact) –

When a Face-to-Face Torque Coupler has an Angular misalignment, one side of the coupler halves is closer than the other, relative to the working-face. This may create some mechanical loading and degrade the torque, based on the severity of the misalignment.

In conclusion, the quality of the alignment between any mechanical or magnetic coupler will greatly impact the systems performance. While Magnetic Torque Couplers are generally more tolerant to mechanical misalignment when compared to conventional mechanical couplers, it is imperative that good integration practices are observed. Please contact Dura Magnetics for design and integration assistance.