At Dura Magnetics, we often receive questions regarding neodymium N52 grade magnets. These magnets are strong, but there are other aspects to consider before determining if they are right for your application. Learn more below about criteria to consider when choosing a neodymium magnet alloy.

What is an N52 magnet?

An N52 magnet is a neodymium magnet that contains an energy product or (BH)Max of 52MGOe (Mega-Gauss Oersteds). The “N52” is an abbreviation referring to the strength of this magnet.

Is N52 the strongest magnet?

Neodymium is the strongest rare earth magnet material, and N52 is among the highest grades of neodymium; consequently, N52 magnets are some of the strongest magnets on the planet.

The number abbreviation, N35, N42, N52, or N55 for example, indicates the strength, or energy product, of the magnet grade. An increase in the number associated with the grade represents an increase in the magnets energy product.

What applications merit an N52 magnet?

With a high strength-to-size ratio, N52 magnets are often used for applications that require a small but strong magnet. Examples include electronics, scientific applications, and household items such as latches that require securely held components.

However, strength isn’t the only factor that should be considered when choosing the desired grade of magnets.

Some customers mistakenly specify N52 neodymium magnets based solely on the material’s high energy product. They may assume a stronger magnet grade will yield better performance, but this is not always the case. The force that an N52 magnet can hold will vary depending on a wide variety of factors.

What other factors should be considered when choosing an N52 magnet?

Although higher energy product material is typically stronger than lower energy product material, N52 magnet strength and the value of its (BH)Max is not the only criteria for selecting material grade.

The following factors should also be considered:

- Operating temperature

- Magnet geometry

- Application requirements

- Cost and value

Why consider cost when choosing N52 magnets?

Many of our customers are surprised to learn that the performance characteristics of N52 may exceed the required application specifications by a significant margin. N52 neodymium magnets are produced from one of the most expensive grades of neodymium; in some instances, a lower grade will perform effectively for a significantly lower price. The magnet specialists at Dura Magnetics provide consultation to help you make the right decision for your application.

What problems can occur with N52 magnets?

Problems with N52 magnets can often be attributed to utilizing overseas suppliers with standards that allow alloy impurities. Therefore, it is critical to properly qualify suppliers prior to ordering.

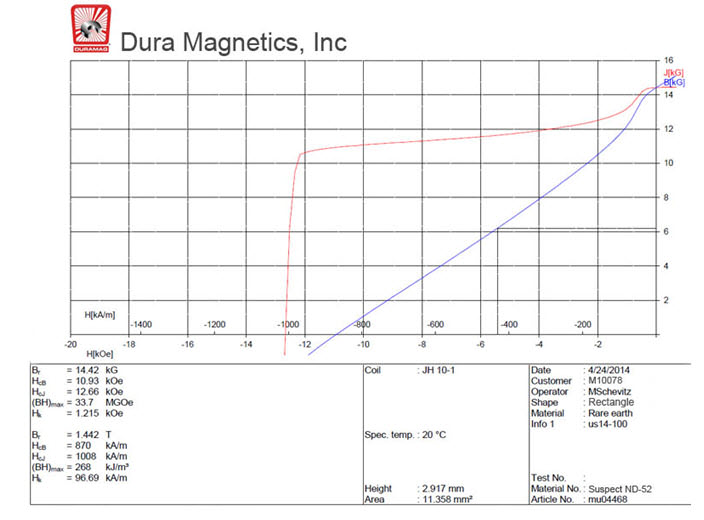

The recent experience of a Dura Magnetics’ customer provides a valuable case study. Due to poor performance, our customer requested testing of a competitor’s material. The supplier asserted the material to be 52MGOe grade; however, Dura Magnetics’ scientific testing and analysis revealed that the material was equivalent to 33MGOe grade.

The figure below illustrates a non-traditional dip in the BH Curve, indicative of impurities in the magnetic alloy.

This customer’s recent experience is unfortunately quite common. Overseas production mills may provide lower quality in order to provide low prices, and distributors lack the resources to adequately analyze the material sent to buyers, resulting in an abundance of low-quality neodymium magnets in the marketplace. In these cases, an unlicensed mill may rubber-stamp inferior material, and the customer suffers.

How can you ensure superior quality N52 magnets?

To ensure proper quality grade, Dura Magnetics verifies performance by testing samples from each shipment, and customer orders are sent with documentation verifying that the licensed neodymium magnet alloys are traceable to the patent holders.

When a customer is in doubt of which material to use or suspects a quality issue, our comprehensive in-house testing and analysis qualifies an existing material type, and our team recommends the most appropriate magnet if an alternative is available.

More questions about N52 magnets?

To discuss the specifics of your application, request a sample, utilize our testing, or to learn more about neodymium magnets, contact Dura Magnetics today.