Two recent discoveries – one related to the re-use of magnetic materials obtained from discarded computer components, the second a potential new trove of rare earth elements found in deep-sea mud near the coast of Japan, may reshape the magnetic marketplace.

New Process for Recycling Magnets

Scientists at the Ames research lab have developed a method to grind and repurpose neodymium magnets found as a component of discarded computers. The process was developed at the U.S. Department of Energy’s Critical Materials Institute (CMI) which focuses on technologies that make better use of materials and eliminate the need for materials that are subject to supply disruptions.

A news release published by the Ames Laboratory explains a process that turns discarded hard disk drive (HDD) magnets into new magnet material in a few steps. This innovative recycling technique addresses economic and environmental issues that often prohibit mining e-waste for valuable materials.

According to Ryan Ott, a scientist at Ames Laboratory and a member of the CMI research team, “with an ever-increasing amount of discarded electronics globally, it made sense to focus on the most ubiquitous source of valuable rare earth magnets in that waste stream—hard disk drives, which have a relatively centralized scrap source.”

Scientists and entrepreneurs have been looking at various methods of extracting rare-earth elements out of e-waste, and some have shown initial promise. However, “some create unwanted by-products and the recovered elements still need to be incorporated into a new application,” said Ott. By eliminating as many processing steps as possible, the Ames laboratory method transitions much more directly from the discarded magnet to an end product – a new magnet.

The Magnet Reclamation Process Described

- Scrapped HDD magnets are collected

- Any protective coatings are removed

- Magnets are crushed into powder

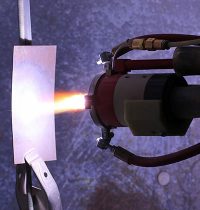

- Plasma spray is used to deposit powdered magnetic material on a substrate

- Coatings can be varied from ½ to 1 mm thick

- Properties of the end magnetic products are customizable depending on processing controls

While the new magnetic material cannot retain the exceptional magnetic properties of the original material, it potentially fills market needs for an economical choice where the performance of a high-strength rare-earth magnet is not required, but lower performance magnets like ferrites are not sufficient.

“This waste reduction aspect of this process is really two-fold; we’re not only reusing end-of-life magnets,” said Ott. “We are also reducing the amount of manufacturing waste produced in making thin and small geometry magnets out of larger bulk materials.”

A (Potential) New Source for Rare Earth Elements

Although we have previously discussed the fact that some rare earth elements are not as rare as their name suggests, the fact remains that China supplies roughly 90% of a primary element used in the manufacture of neodymium magnets. Therefore, a recent discovery in the mud at sea-bottom off the coast of Japan is interesting because it may provide an alternative source not only for neodymium, but other elements.

An estimated 16 million tons of that mud may hold massive, “semi-infinite” stores of valuable rare earth minerals according to a research paper published January 2018 in the journal Nature. In that paper, a Japanese scientific research team proposes a model for extracting rare-earth elements and yttrium (REY) found in high concentration (over 5,000ppm total REY content) within deep-sea mud discovered in the western North Pacific Ocean near Minamitori shima Island, Japan, in 2013.

This REY-rich mud has great potential as a rare-earth metal resource if it can be successfully commercially extracted because of the enormous amount available and its advantageous mineralogical features. The Nature article estimated the resource amount in REY-rich mud with Geographical Information System software and established a mineral processing procedure proposed to enhance its economic value.

Can Japan Provide an Alternative Source for Magnetic Material?

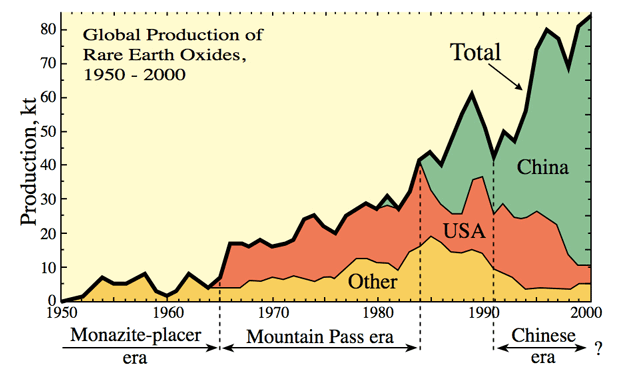

From the 1960s to the ‘80s, the United States supplied the world with rare earth elements. A single mine in California named Mountain Pass was the source of that material. In the ‘90s, China entered the market and drove magnet prices down, making the Mountain Pass mining operation unprofitable and eventually leading to its closure in 2002. From that point forward, China became the predominant supplier.

Global production of rare earth oxides,1950 to 2000. Image Source: United States Geological Survey

In 2010, China drove the price of rare-earth elements up as much as 10 times by cutting its export quota.

A concern expressed in a Wall Street Journal article quotes Professor Yutaro Takaya Waseda, leader of the Japanese research team, saying that “In the event of a conflict, [China] could jack up prices for the West and its allies, or even shut them out altogether. In this eventuality, the Minamitori hoard would be a lifeline. It is important to secure our own source of resources, given how China controls the prices.” Both the U.S. Department of Energy and the European Union have issued warnings about shortages of rare earths as China’s own consumption of them increases.

How Would REY be Extracted From Mud?

The Nature Scientific Report describes a hydrocycle using centrifugal forces to quickly separate out a lot of the unnecessary materials in the sea mud. A hydrocycle utilizes a conical shape, continuously accelerating the velocity of water flowing through it, increasing centrifical forces and maximizing separation.

But according to an article published in The Verge, this method is unproven.

“Nobody has ever done it before, and no-one has proved it can work at an industrial scale,” says Professor Frances Wall of the Exeter University’s Camborne School of Mines. Professor Wall told The Verge that the Japanese team are doing “some nice work,” but says a huge amount of research has yet to be done before the seabed becomes a reliable source of these important elements. “There have been literally hundreds of exploration projects [that have found rare earth metals] and they’ve not been able to go forward through production because they can’t prove they’ll make any money,” says Wall.

Will the Minamitori Find Prove Significant?

The primary challenge is in the processing of the mud and in getting the rare earth elements out of the sea and into a usable form.

China’s production of rare earth materials, although very substantial, fluctuates year-by-year.

Although there are other sources for these elements, and ways to circumvent China’s control of the global supply, resource-poor Japan may continue with research in hopes of getting more control over next-generation technologies and weapons systems.

While extracting the elements would likely be costly, the roughly 965-square-mile seabed near the island is believed to contain more than 16 million tons of rare-earth oxides. If accurate, this is estimated to hold 780 years’ worth of the global supply of yttrium, 620 years’ worth of europium, 420 years’ worth of terbium and 730 years’ worth of dysprosium.

More research needs to be done on methods of extracting the rare earths continuously, Prof. Takaya said. A Japanese consortium of government-backed entities, corporations including Toyota Motor Corp., and research institutions hopes to conduct a feasibility test within the next five years, the researchers said.