A material’s magnetic permeability refers to its ability to align itself with a magnetic field. A high magnetic permeability indicates that a material easily aligns itself to a magnetic field. If it is difficult to align to the magnetic field, the material is said to have low magnetic permeability.

Magnetic permeability can also be thought of as how easily a material can be magnetized. The more permeable the material, the easier it is to magnetize – therefore, it has high magnetic permeability.

Magnetic permeability is one key to the magnet fabrication process.

Magnetic Permeability – Key Takeaways

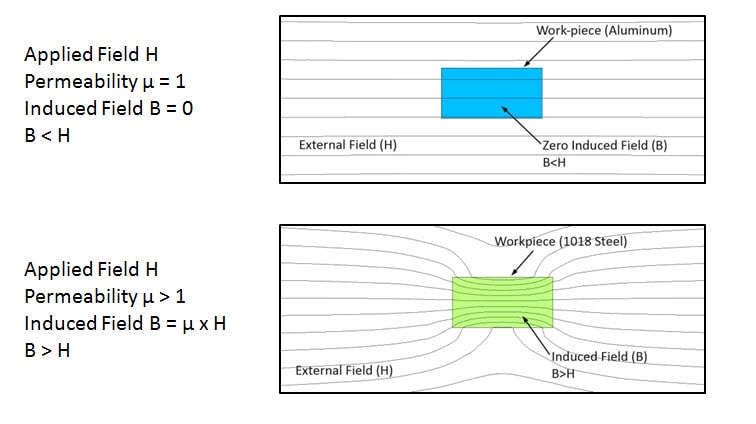

- Magnetic permeability is the characteristic of a material which represents the establishment of an induced internal magnetic field by an external magnetic field. The magnetic permeability is the proportionality between the induced field and the applied magnetic field strength.

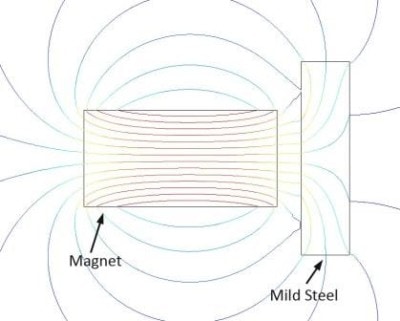

- A ferrous material is attracted to a permanent magnet because the permanent magnet induces magnetism within the ferrous material. The permanent magnet’s field and the newly induced field in the ferrous material interact and attract.

- A material’s permeability indicates how easily an external magnetic field can induce an internal field in the material. The stronger the internal field, the stronger the force of attraction.

- A material’s permeability is not constant but rather changes based on several factors. These factors include temperature, how it was processed, the intensity of the applied drive field, and humidity.

Why are some materials magnetic while others are not?

Two magnets attract to each other because their fields interact. If there is no field, there is no interaction, and therefore no attraction.

Materials with a magnetic field can attract other materials with such a field. Materials that are not magnets do not have a net external magnetic field, and do not attract objects; however, some metal alloys can have a net field created by applying an external field.

Magnetic Permeability and Induced Magnetic Fields

By applying an external field, some metal alloys can have a net field created. This created, or induced, field is only present when the external drive field is applied. Once the external drive field is removed, the induced field is also removed.

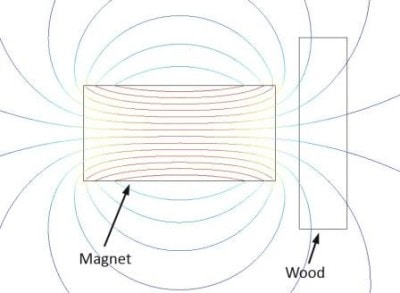

For example, a permanent magnet is attracted to a ferrous object because magnetism is induced in the object by the magnetic field emanating from the permanent magnet. A magnet is not attracted to materials such as wood because no internal field is induced in the wood. With no induced internal field, there is no field interaction and no attraction.

Two pieces of steel do not attract to each other because they do not induce fields in each other: no field, no interaction, no attraction.

The degree of the induced magnetism is related to the ferrous material’s magnetic permeability, expressed as a unitless value designated by the Greek letter mu (μ). The higher the material’s permeability, the greater the magnetic induction and the resulting force of attraction.

What do magnets attract to?

It is useful to compare high magnetic permeability and low magnetic permeability materials to better understand the difference in what magnets are attracted to.

Low permeability materials are materials that are not attracted to a magnet, such as air, wood, plastic, and brass. There is no magnetism induced in them by an external magnetic field. Therefore, they are not attracted by a magnet.

High permeability materials such as ferrous materials, Nickel, and Cobalt alloys have a high permeability. Therefore, magnetic fields can be induced in them when exposed to an external magnetic field.

Example of Magnetic Permeability in Mild Steel

Induced Magnetism in an alloy (B) = alloy’s permeability (μ) X external applied drive field (H)

Using mild steel as an example, we see the equation B = μH thus: Induced (Internal Field) = ~15,000 Gauss = (30) x 500 Oersted.

The 15,000 Gauss field induced in the mild steel interacts with the applied magnetic field, and there is attraction. In Figure 1, above, it can be observed how the flux lines are denser in the steel, showing the induced field, as well as how the flux Lines “bend” in the steel alloy. The steel’s magnetic properties bias, or interact with, the magnet’s magnetic flux lines — the field.

Example of Magnetic Permeability in Wood

Using wood as an example, we see the equation thus: Induced (Internal Field) = 500 Gauss (1) x 500 Oersted.

The only field in the wood is from the externally applied magnetic field, and no new field is induced to interact with the applied field. Therefore, there is no attraction.

In Figure 2, see how the flux Lines are not biased by the wood, and there is no induced field. The flux Lines do not “bend” in the wood; they pass through, as if it is not there. There is no field-to-field interaction and no attraction.

Magnetic Permeability Can Change

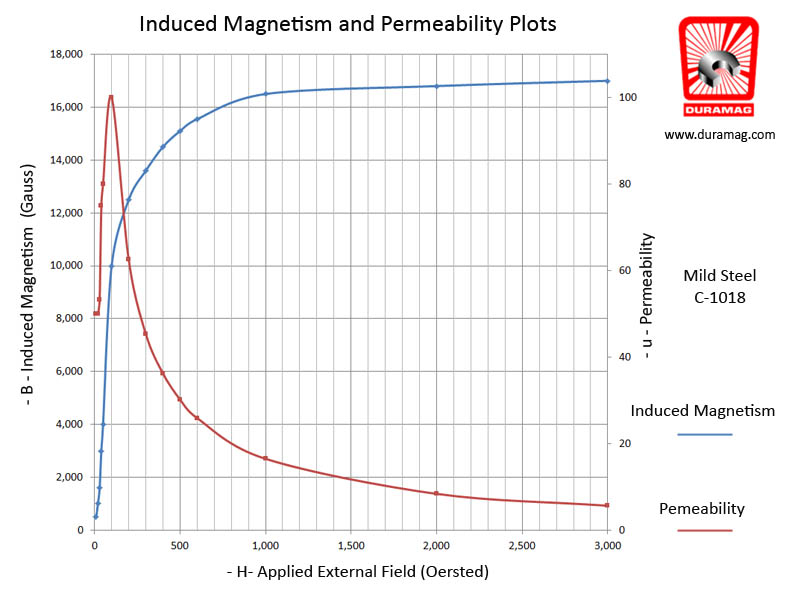

The magnetic permeability of a material is not constant. For a given temperature, it changes based on the intensity of the applied external magnetic field (H). The relative aspect of permeability is more apparent when illustrated with a graph depicting a material’s permeability relative to the applied external field.

Often, technical books will list a material’s magnetic permeability as a constant, but this can be inaccurate and quite misleading. For instance, Figure 3 is a plot for mild steel C-1018 that illustrates the Induced Magnetism (G) for various applied Field Strength levels (H). It also depicts the corresponding magnetic permeability at each applied field strength level. The permeability for C-1018 may be advertised as 100 (in the CGS unit system), but this is the peak value, and it is less than 20 over most of the curve.

Why Magnetic Permeability Is Important

A material’s permeability is important because it allows you to anticipate the performance of a magnet when used in a design. For instance, a customer may want to pick up automobile exhaust tubing with a magnetic end effector on a robot-arm. When the tube is made from an aluminized mild steel alloy, the magnet handling device may work effectively; however, when the tube is 410 SS, the tube may be dropped. The force of attraction between the handling magnet and the tube is greater with the aluminized mild steel than the 410 stainless because the mild steel has a higher permeability than the 410 SS.

When designing a product or system that utilizes magnetic fields, always consider the quality of your material’s magnetic permeability. Whether you’re looking for high-permeability or low-permeability materials, the experts at Dura Magnetics are standing by to help. Contact us for professional consultation on your next project and request a quote.