So What Is Maximum Energy Product ((BH)max), Magnet Grade and MGO?

The term Maximum Energy Product ((BH)max) is a commonly used, but often misunderstood figure of merit of magnets. The (BH)max is an Energy Density and it is oftentimes used to denote grade. The grade convention is especially used for Rare Earth magnets, (Neodymium Iron Boron Magnets and Samarium Cobalt Magnets). For instance, a grade 48 Neodymium Iron Boron magnet will generally have an advertised (BH)max of 48 MGOe. (The unit MGOe, Gauss•Oerstedx10^6, or Mega-Gauss•Oersted is used in the CGS (Centimeter-Gram-Second) unit system. The Maximum Energy Product in the SI (Systeme International) unit system is Joules/m^3.)

This convention seems reasonable, but it does have limitations because it does not allow for the prediction of magnetic performance. Generally, a magnet with a higher (BH)max will be stronger than a magnet with a lower (BH)max, but that still does not allow us to predict performance relative to magnetic field density or flux generation.

In order to predict the performance of a magnet in a particular application, other magnetic characteristics of the magnet material and the physical geometry of the magnet must be known. Predicting performance is not in the scope of this article, but the magnet geometry is pertinent to the Maximum Energy Product discussion.

Formal Definition of Maximum Energy Product:

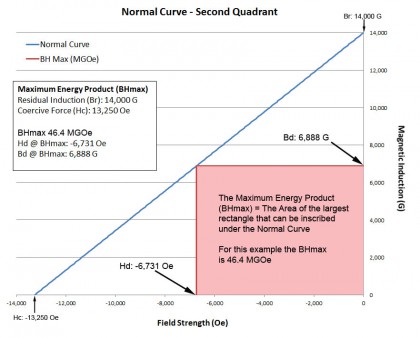

The Maximum Energy Product or (BH)max of a magnet is an Energy Density and it is equivalent to the area of the largest rectangle that can be inscribed under the normal curve as shown below (figure 1):

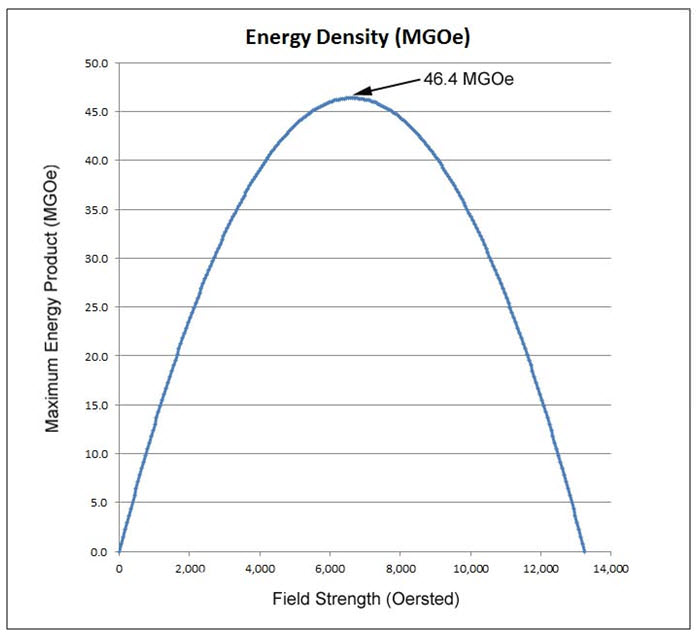

It is also the vertex of a parabola comprised of the product of points constituting the Normal Curve (Magnetic Induction and Field Strength) plotted against the Field Strength as illustrated here (figure 2):

(BH)max Technical Explanation:

(BH)max is a volume independent magnetic characteristic, meaning a small and large magnet made from the same ND-48 Neodymium Iron Boron magnet alloy will have the same (BH)max, although though they create vastly different magnetic fields or flux. The Maximum Energy Product, or (BH)max, is attained when the magnet is operating at the highest Induction level (Gauss) and at the smallest volume for a particular pole cross-section. Larger volumes of the magnet will produce larger magnetic fields and more flux, though the magnet may not be operating at (BH)max.

In relation to the BH Curve or Demagnetization Curve, the second quadrant of a magnet’s hysteresis curve, the Maximum Energy Product is the largest rectangle that can be inscribed under the Normal Curve (see figure 1). The rectangle’s vertex on the X axis (Field Strength) is the operating point Hd at (BH)max, while the vertex on the Y axis (Magnetic Induction) is the operating point Bd at (BH)max.

Also, if the (H-B) data-points for the Normal Curve are known, their product can be calculated and then plotted against the Field Strength, (X axis). This plot will generate a parabola and the vertex of the parabola will be at the Maximum Energy Product for the particular grade in the units of MGOe, if B is in Gauss and H is in Oersteds (see figure 2).

Commercial magnet magnetic characteristics are advertised with tolerances. The range of the Residual Induction (Br) and the Coercive Force (Hc) change where the operating points, Hd and Bd occur for the (BH)max. This is why there is an effective range for the Maximum Energy Product.

For a magnet to operate at its (BH)max it must have a particular geometry. This geometry is a commonly used ratio in magnetic design and it is the ratio of the Magnetic Length to the Diameter of the Magnet, L/D. (For non-round magnets, the diameter of a circle with an equivalent area of the non-round pole is used.) Since this is a ratio, there are an infinite number of possibilities of magnet geometries for any particular magnet grade.

When a particular magnet is operating at (BH)max it can be said to have the highest efficiency relative to energy density. Again, when a magnet operates at (BH)max it may not be generating a large enough magnetic field for a particular application and therefore, a greater volume may be required. Most magnets used in applications are not designed to operate at (BH)max.

Interested in Learning More?

Do you have technical questions about the design and manufacture of magnets? Send your questions to our engineering staff, or contact us at 1-800-492-7939.