Several factors can cause a permanent magnet to lose some or all its magnetic field, an occurrence of which can have adverse effects on your application.

Learn how a permanent magnet can become demagnetized, how demagnetization works, and what physical conditions to preserve or avoid in order to maintain the desired magnetization in your permanent magnet application.

What is meant by demagnetization?

Demagnetization refers to the reduction or complete removal of magnetic properties from a magnet.

Permanent magnets operate based on alignment of micro regions within an alloyed material. These small regions are called domains, each of which acts like a microscopic magnet within the larger whole.

Part of the process of developing permanent magnets involves placing high strength magnetic material –typically either aluminum-nickel-cobalt (alnico), strontium-iron (known as ceramics or ferrites), neodymium-iron-boron, or samarium-cobalt – within a strong magnetic field.

During the process of magnetizing the material, the individual domains, which normally point in all directions, become aligned in the direction of the magnetic field. When nearly all domains are aligned to the originating magnetic field, the material has become a permanent magnet.

When you demagnetize a magnet, its magnetic domains are no longer completely aligned. It was the alignment of those domains that provided the material’s magnetic properties. When the magnetic field (domain alignment) is disrupted, the magnet has been demagnetized.

How are permanent magnets demagnetized?

How can something referred to as a permanent magnet be demagnetized? People are sometimes confused by the terminology of “permanent” magnet as opposed to a “temporary” magnet. Temporary magnets behave as magnets only while attached to or close to something that emits a magnetic field. They rapidly lose their magnetic properties when the source of the magnetic field is removed.

Conversely, a permanent magnet, under normal operating conditions, generally retains its persistent magnetic field independently. However, the demagnetization of permanently magnetized materials can still occur under certain conditions including exposure to high heat, collision with other objects, volume loss, and exposure to conflicting magnetic fields.

Heat

One of the most common reasons for demagnetization is an increase in temperature. Increased heat means increased atomic movement, which eventually overpowers the alignment of magnetic domains. The Curie temperature is the temperature above which a magnetic alloy completely and irreversibly loses its permanent magnetic properties. However, demagnetization will also occur at varying levels as the temperature of a magnet approaches its Curie point. The level of demagnetization varies greatly depending on the material and grade of a particular magnet and is described by the demagnetization curve for that magnet.

In general, certain permanent magnet materials are more susceptible than others to demagnetization with increased temperature. Neodymium magnets are generally the most susceptible to elevated operating temperatures and typically resist demagnetization until the working temperature reaches about 100°C. Neodymium magnetic materials capable of operating above 220°C are available, however these materials can become quite expensive. For samarium cobalt magnets, that limit is 350°C. Alnico magnets offer the best temperature characteristics of any standard production magnet material available, capable of being used for continuous duty applications where temperature extremes of up to 540°C can be expected.

When operating at elevated temperatures, it is important to know the permeance coefficient for a specific size of the magnetic material you are working with. The size, material, and operating temperature all play a role in determining the overall effectiveness of a magnet for a given work purpose. For neodymium magnets, please use our permeance coefficient calculator to help determine whether or not a particular magnet size will demagnetize and ultimately lose effectiveness at the operating temperature your application requires.

When a permanent magnet is exposed to increased temperatures for a length of time, the electrons will be forced out of alignment and the magnet will be demagnetized, either partially or completely. The resulting demagnetization may be reversible, or it may be irreversible.

Collision and loss of volume

Another factor that can demagnetize a permanent magnet is collision — the impact of another object on the magnet. Repeatedly striking the magnet with a hammer, for example, will interfere with the movement of its atoms and affect the alignment of the north and south poles of the magnet, causing its demagnetization.

Collision can also affect the physical integrity of the magnet, and the resulting loss in volume can also have an adverse effect on magnetization. That’s why loss of volume is considered another factor in the demagnetization of permanent magnets; erosion or oxidation caused by excess humidity can also affect the physical properties and therefore the magnetic properties of the magnet.

Conflicting magnetic fields

Exposure to adverse, outside magnetic force fields can demagnetize a permanent magnet. When there is another magnetic field around the magnet, it can act as a demagnetizing force, and the magnet can become damaged.

This is part of the reason why proper storage of your permanent magnets is so important; it preserves the magnetic properties by ensuring that your magnets are not only protected from collision but also in alignment in terms of magnetic fields.

Running an AC current in proximity can also have this effect on a magnet, resulting in demagnetization.

The demagnetization curve calculator

The demagnetization curve demonstrates the magnetic qualities of a particular magnet as plotted on an axis, thereby giving a more complete picture than a single point. A demagnetization curve is often used for the design of magnetic components for this reason.

More specifically, the curve shows the ratio of flux density (B) to the magnetizing field (H), the resulting intersecting point being the permeance coefficient.

Dura’s demagnetization calculator helps you choose a design path by illustrating a chosen magnet’s demagnetization at a range of set points. For example, you can find the permeance coefficient of an N35, disc-shaped magnet that is 3” in diameter and 0.1” thick. Simply change the material and other parameters to discover the demagnetization curve for your magnet of choice. This calculator is useful for determining the design of your magnetic assembly.

Of course, the experts at Dura can help, too. We have the scientific and technical expertise to help you identify the best magnet for your needs. Contact us with questions on your application.

Can you “re-magnetize” a magnet?

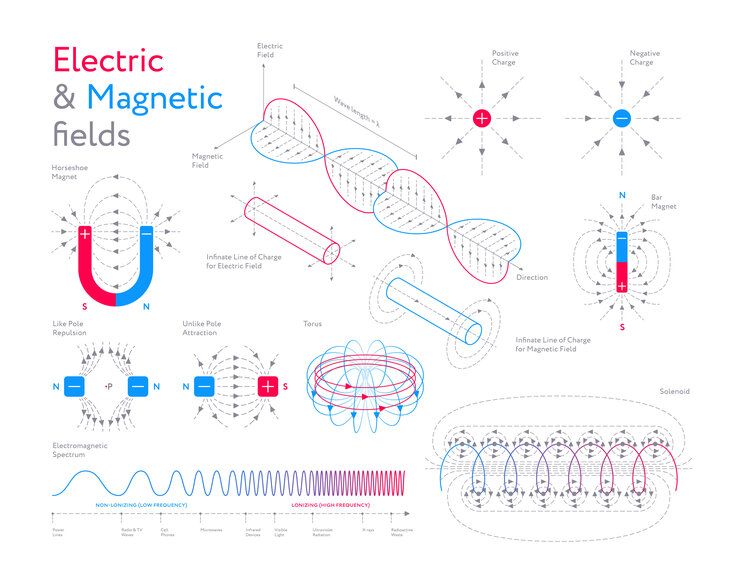

Depending upon the cause of demagnetization and the duration of the condition, it may be possible to repurpose the magnetic material and return the lost magnetic properties. One method used to restore a permanent magnet is through the use of a solenoid. When a current is activated through the coiled metal wire of a solenoid, it may be adequate to restore the magnetic field of the magnet.

The permanent magnet experts

Demagnetization can adversely affect the functionality of the magnet and the application for which your magnet is a component. Therefore, it is important to recognize and engineer magnetic assemblies to avoid physical situations that can demagnetize.

Dura Magnetics continues to lead our industry in the design, engineering, and fabrication of custom magnets and magnetic assemblies. Contact our engineering team for more information about your specific requirements for custom technical magnets or magnetic assemblies or to request a quote.